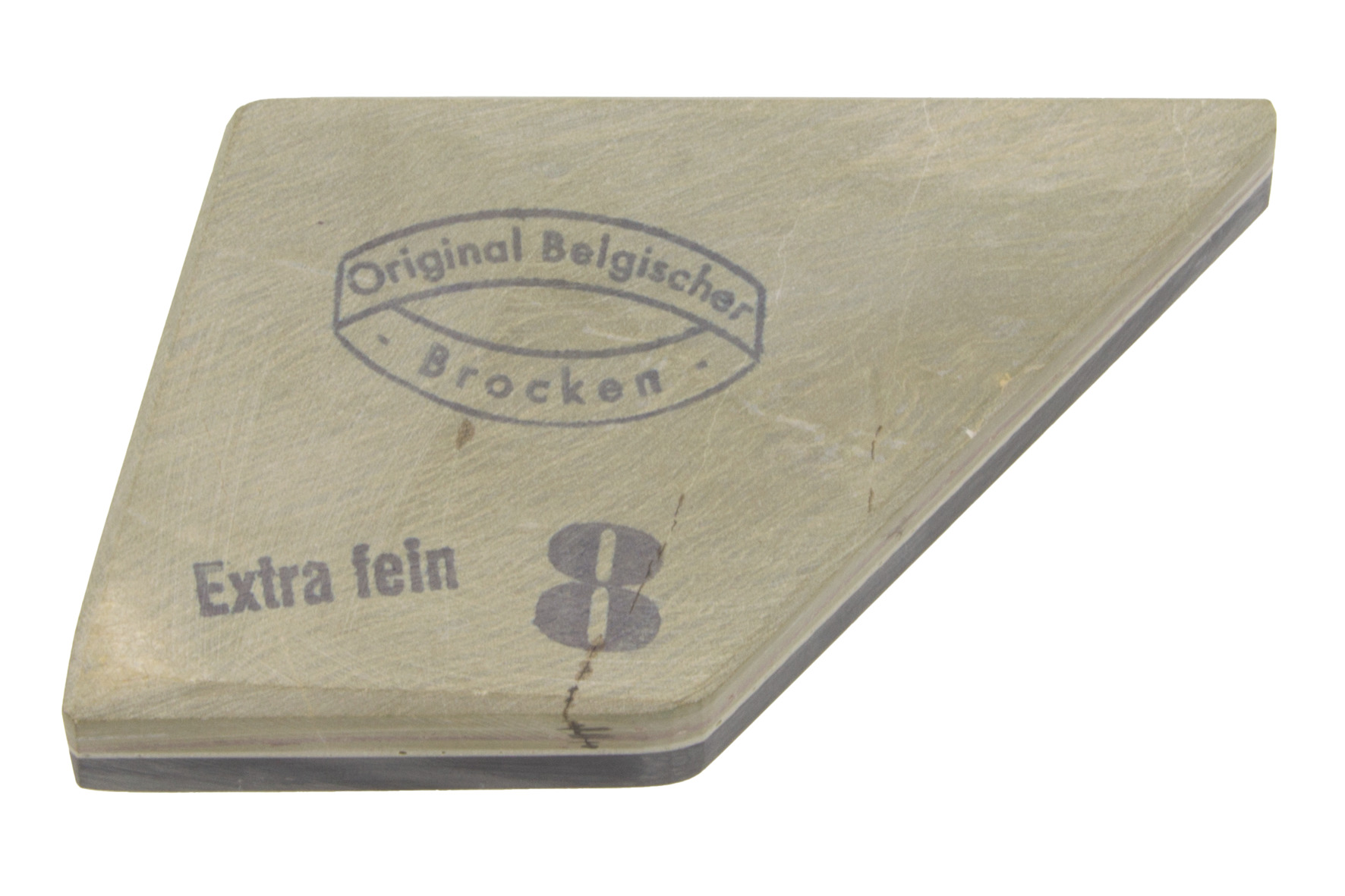

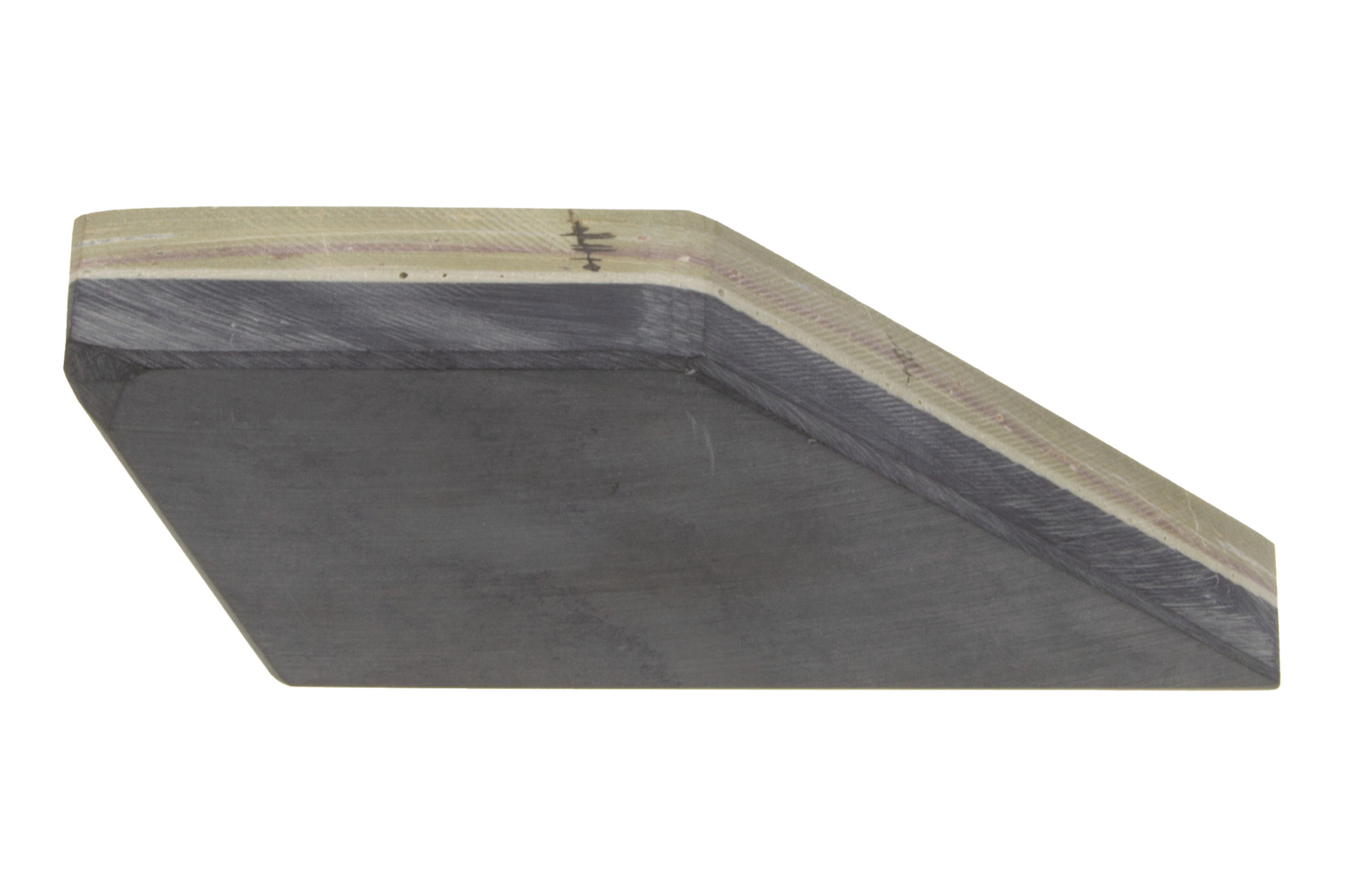

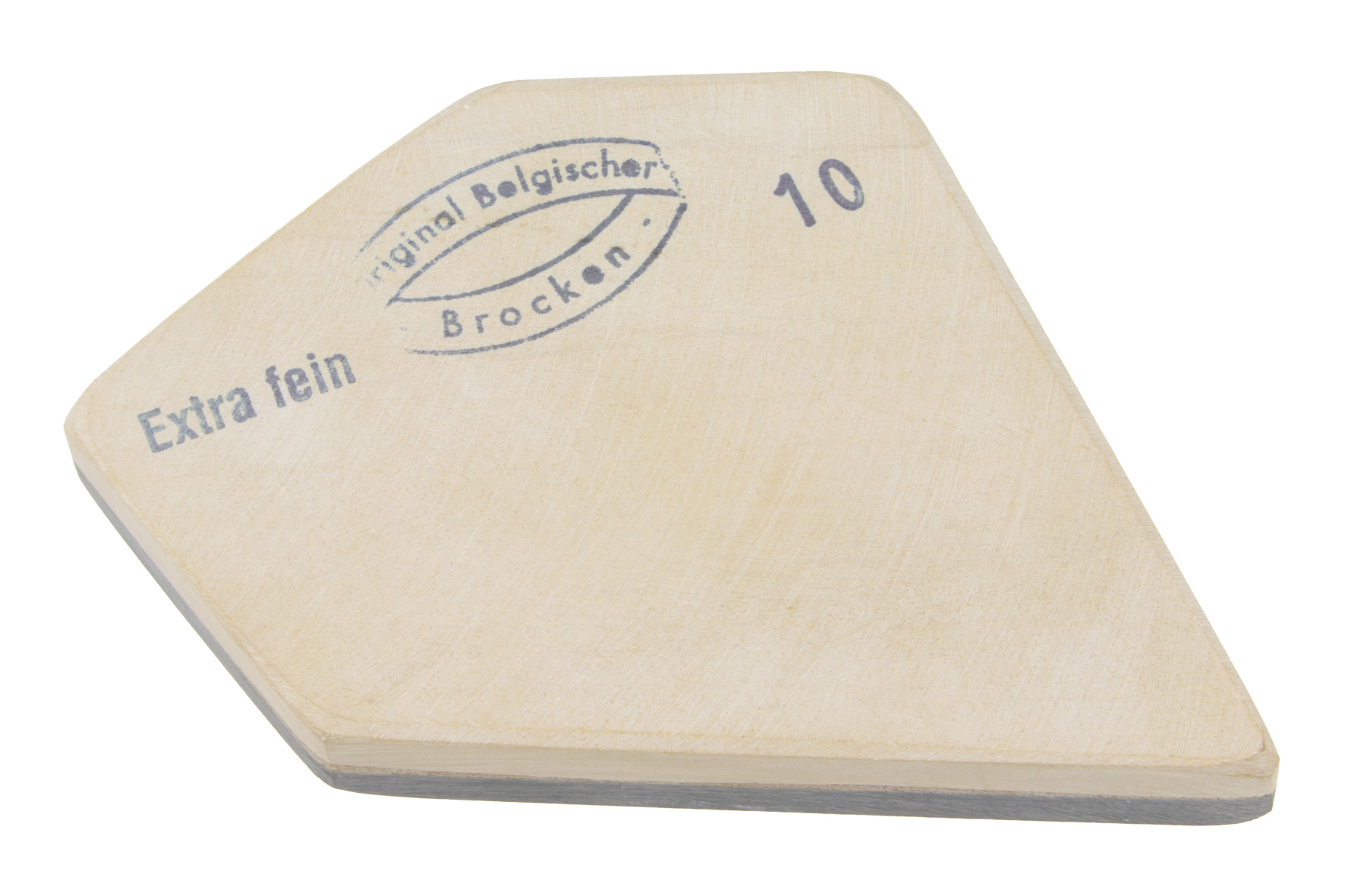

5349 Belgian crumb – sharpening stone, form G

Optimal for polishing, due to the high grit number blades can be ground razor sharp. The sharpness lasts up to seven times longer. 8,000 - 10,000 grit.

Use with distilled water. Size variation of +/-10 %.

| Item No | Designation | Weight | Length | Width | Height |

|---|---|---|---|---|---|

| 534909 | Belgian crumb - sharpening stone, form G 130x40x20 mm | 300 g | 90 mm | 35 mm | 10 mm |

Manufacturer information (GPSR)

MANUFACTURER ACCORDING TO THE EU GENERAL PRODUCT SAFETY REGULATION (GPSR)

STUBAI ZMV GmbH

Dr. Kofler Straße 1

A-6166 Fulpmes

Phone: +43 5225 6960 211

Email: office@stubai.com

Safety Instructions for Sharpening Tools (Sharpening Stones, Buffing Wheels, Honing Oil)

General Information:

• Suitable tool: Always use the sharpening tool specifically designed for the respective task. Using an unsuitable tool increases the risk of accidents and can make the work more difficult.

• Sharpening tools may only be used by persons with limited physical, sensory or mental abilities, or lacking experience and/or knowledge, if they are supervised by a person responsible for their safety, have received instructions on how to use sharpening tools, and have understood the resulting hazards.

• Children may only use sharpening tools if they are over 8 years old and are supervised by a person responsible for their safety, have received instructions on how to use sharpening tools, and have understood the resulting hazards.

• Keep packaging films away from children; risk of suffocation!

Intended Use:

• Safety is only ensured when the tool is used as intended. Use the tool exclusively for its designated purpose.

Improper Use:

• Sharpening tools are specifically intended for sharpening chisels or carving tools. Use buffing wheels only in combination with honing oil.

Inspection Before Use:

• Ensure tool integrity: Check all sharpening tools before use for cracks, damage or wear. A defective tool may result in inefficient sharpening and unnecessary risks.

• Do not use damaged sharpening tools: Defective sharpening tools must not be used and must be taken out of service immediately.

Personal Protective Equipment:

• Wear safety goggles: Use safety goggles to protect yourself from chipping material.

• Hand protection: Wear robust work gloves that provide a secure grip and protect against splinters or skin injuries or irritation.

• Safety footwear: Wear safety shoes with a metal or plastic toe cap to protect your toes.

Specific Safety Instructions for Sharpening Stones:

• Use a non-slip surface: Ensure that the sharpening stone is placed on a stable, non-slip surface to prevent slipping or tipping during use.

• Water or oil additive: Use sharpening stones only with water or the designated oil. Using the wrong liquid may damage the stone and impair sharpening performance.

• No excessive pressure: Do not apply excessive pressure when sharpening with stones. Too much pressure may damage the blade and reduce the effectiveness of the stone.

• Safe handling: Always hold the sharpening stone firmly with both hands to ensure a secure grip and precise handling. Wear protective gloves if necessary to avoid injuries from slipping.

Specific Safety Instructions for Buffing Wheels:

• Set the correct speed: Ensure that the buffing wheel is operated at the correct speed. Excessive speed may cause overheating and damage to the tool.

• Wear protective clothing: When working with buffing wheels, always wear appropriate protective equipment such as safety goggles and hearing protection to protect yourself from dust and sparks.

• Even pressure: Apply even pressure when sharpening with the buffing wheel to ensure uniform sharpening and avoid overheating.

• Stabilize the workpiece: Stabilize the workpiece during processing to prevent slipping and injuries.

Specific Safety Instructions for Honing Oil:

• Do not use near open flames: Honing oil is flammable and must never be used near open flames or hot surfaces. Always store honing oil in a cool, dry place.

• Ensure adequate ventilation: Ensure that the work area is well ventilated when using honing oil to minimize fumes and reduce health risks.

• Caution when applying: Use honing oil sparingly and apply it evenly to the sharpening tool to avoid flooding and contamination. Wipe off excess oil immediately after use.

Maintenance, Care and Storage:

• Regular inspection: Regularly check the sharpening performance of the tools and replace the honing oil when it loses effectiveness. Well-maintained sharpening tools ensure better results and longer service life.

• Cleaning after use: After use, sharpening tools should be thoroughly cleaned and stored dry to ensure long life and optimal sharpness.

• Keep clean: Ensure that sharpening stones, buffing wheels and honing oil containers are clean and free from deposits. Dirt and residues may impair sharpening performance and damage the tools.

• Storage: Store tools out of reach of children and persons with limited physical, sensory or mental abilities, in a safe, dry place such as a toolbox or tool wall to prevent accidents and damage.

Special Notes:

• No improvisation: Use sharpening tools only for their intended purpose. Do not use unsuitable liquids or materials to enhance sharpening performance.

• Safe workspace: Ensure that the workspace is free from unnecessary objects and tripping hazards to avoid accidents during sharpening.

• Transport: Ensure that sharpening tools are securely fastened during transport.

This text has been partially translated with the support of AI technology.

STUBAI ZMV GmbH

Dr. Kofler Straße 1

A-6166 Fulpmes

Phone: +43 5225 6960 211

Email: office@stubai.com

Safety Instructions for Sharpening Tools (Sharpening Stones, Buffing Wheels, Honing Oil)

General Information:

• Suitable tool: Always use the sharpening tool specifically designed for the respective task. Using an unsuitable tool increases the risk of accidents and can make the work more difficult.

• Sharpening tools may only be used by persons with limited physical, sensory or mental abilities, or lacking experience and/or knowledge, if they are supervised by a person responsible for their safety, have received instructions on how to use sharpening tools, and have understood the resulting hazards.

• Children may only use sharpening tools if they are over 8 years old and are supervised by a person responsible for their safety, have received instructions on how to use sharpening tools, and have understood the resulting hazards.

• Keep packaging films away from children; risk of suffocation!

Intended Use:

• Safety is only ensured when the tool is used as intended. Use the tool exclusively for its designated purpose.

Improper Use:

• Sharpening tools are specifically intended for sharpening chisels or carving tools. Use buffing wheels only in combination with honing oil.

Inspection Before Use:

• Ensure tool integrity: Check all sharpening tools before use for cracks, damage or wear. A defective tool may result in inefficient sharpening and unnecessary risks.

• Do not use damaged sharpening tools: Defective sharpening tools must not be used and must be taken out of service immediately.

Personal Protective Equipment:

• Wear safety goggles: Use safety goggles to protect yourself from chipping material.

• Hand protection: Wear robust work gloves that provide a secure grip and protect against splinters or skin injuries or irritation.

• Safety footwear: Wear safety shoes with a metal or plastic toe cap to protect your toes.

Specific Safety Instructions for Sharpening Stones:

• Use a non-slip surface: Ensure that the sharpening stone is placed on a stable, non-slip surface to prevent slipping or tipping during use.

• Water or oil additive: Use sharpening stones only with water or the designated oil. Using the wrong liquid may damage the stone and impair sharpening performance.

• No excessive pressure: Do not apply excessive pressure when sharpening with stones. Too much pressure may damage the blade and reduce the effectiveness of the stone.

• Safe handling: Always hold the sharpening stone firmly with both hands to ensure a secure grip and precise handling. Wear protective gloves if necessary to avoid injuries from slipping.

Specific Safety Instructions for Buffing Wheels:

• Set the correct speed: Ensure that the buffing wheel is operated at the correct speed. Excessive speed may cause overheating and damage to the tool.

• Wear protective clothing: When working with buffing wheels, always wear appropriate protective equipment such as safety goggles and hearing protection to protect yourself from dust and sparks.

• Even pressure: Apply even pressure when sharpening with the buffing wheel to ensure uniform sharpening and avoid overheating.

• Stabilize the workpiece: Stabilize the workpiece during processing to prevent slipping and injuries.

Specific Safety Instructions for Honing Oil:

• Do not use near open flames: Honing oil is flammable and must never be used near open flames or hot surfaces. Always store honing oil in a cool, dry place.

• Ensure adequate ventilation: Ensure that the work area is well ventilated when using honing oil to minimize fumes and reduce health risks.

• Caution when applying: Use honing oil sparingly and apply it evenly to the sharpening tool to avoid flooding and contamination. Wipe off excess oil immediately after use.

Maintenance, Care and Storage:

• Regular inspection: Regularly check the sharpening performance of the tools and replace the honing oil when it loses effectiveness. Well-maintained sharpening tools ensure better results and longer service life.

• Cleaning after use: After use, sharpening tools should be thoroughly cleaned and stored dry to ensure long life and optimal sharpness.

• Keep clean: Ensure that sharpening stones, buffing wheels and honing oil containers are clean and free from deposits. Dirt and residues may impair sharpening performance and damage the tools.

• Storage: Store tools out of reach of children and persons with limited physical, sensory or mental abilities, in a safe, dry place such as a toolbox or tool wall to prevent accidents and damage.

Special Notes:

• No improvisation: Use sharpening tools only for their intended purpose. Do not use unsuitable liquids or materials to enhance sharpening performance.

• Safe workspace: Ensure that the workspace is free from unnecessary objects and tripping hazards to avoid accidents during sharpening.

• Transport: Ensure that sharpening tools are securely fastened during transport.

This text has been partially translated with the support of AI technology.